Advertisements

Hard Disk Drive

- Effective I/O device – Secondary/auxiliary memory

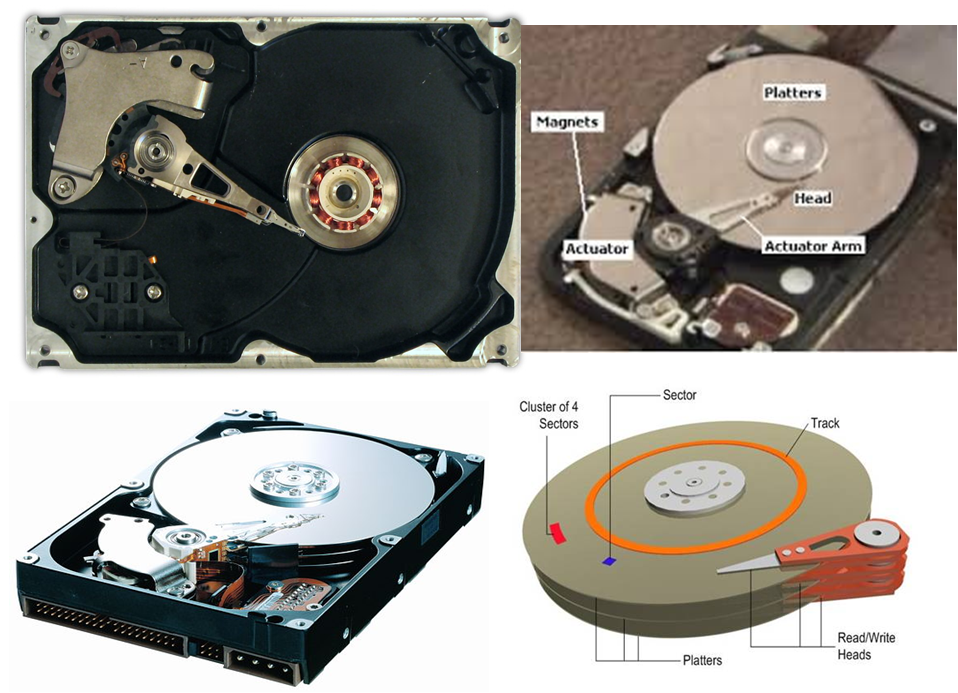

- Components

- One or more platters on disks mounted with common spindle

- Platter has 2 magnetic surface – top & bottom

- Oxide coating on aluminum disk surface & currently thin film disks affixed to substrate

- R/W head flies over disk

- Earlier ferrite heads & now thin film heads

Working

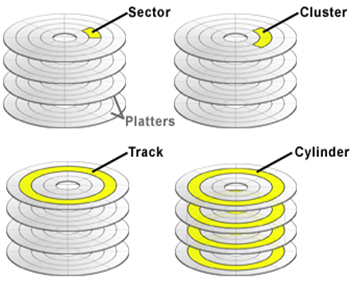

- Data recorded on tracks

- Cylinders – tracks on a specific circle

- No. of cylinders = no. of tracks in a surface

- Data – MFM form & serial through singe wire (DATA + CLOCK)

- Control signals inform exact location of storage

- Cylinder number, surface number, etc.

- Disk rotation: 2400, 4800, 7200 rpm

Types I

1. Removable Disk Drive

- Disks can be removed when not used

- So, Any number of disk packs

- Transfer of data from one disk to another

2. Fixed Disk Drive

- Disk cannot be removed from disk drive

Types II

1. Single head assembly Drive

- One head for each surface

- Heads mounted on one spindle & move together

- All head positioned in same cylinder

2. Dual head assembly Drive

- Two heads for each surface

- One set covers 1st half & 2nd set covers 2nd half of cylinder

Types III

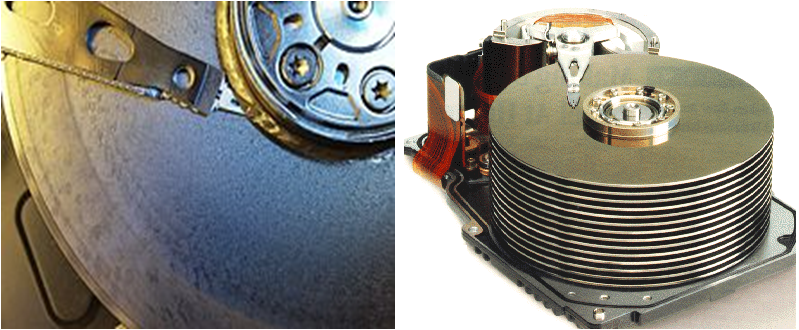

1. Winchester Disk Drive

- R/W heads in a sealed enclosure

- Head flies close to hard disk less than 19 micro inches

- heads park on parking / landing zone – no data written

- Surface of disk is lubricated – prevent damage to head or track

- Higher track densities

- No preventive maintenance

- Built-in preventive system against head crash – back up

2. Non – winchester Disk Drive

- Obsolete

- used till 1973

Types IV

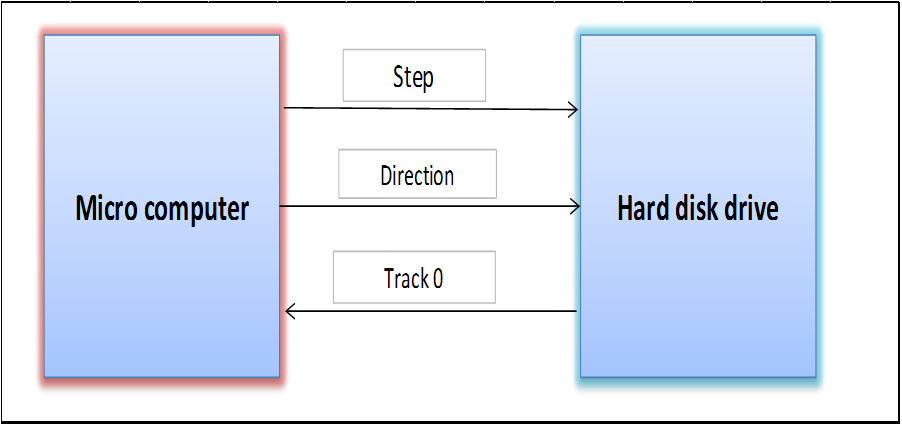

1. Open loop Disk Drive

- Stepper motor for head movement

- Track-0 is reference point

- STEP Pulse issued to stepper motor for head move on track

- No. of step pulses decide total distance of head movement

- No feed back system to verify head movement

- S/w tracks formatting info to verify head correctness

- Direction signal – direction of movement of stepper motor (forward & backward)

- When head is on track0, HDD sends TRACK0

- Present track number is with ref to track0 & Low cost

Open loop Disk Drive

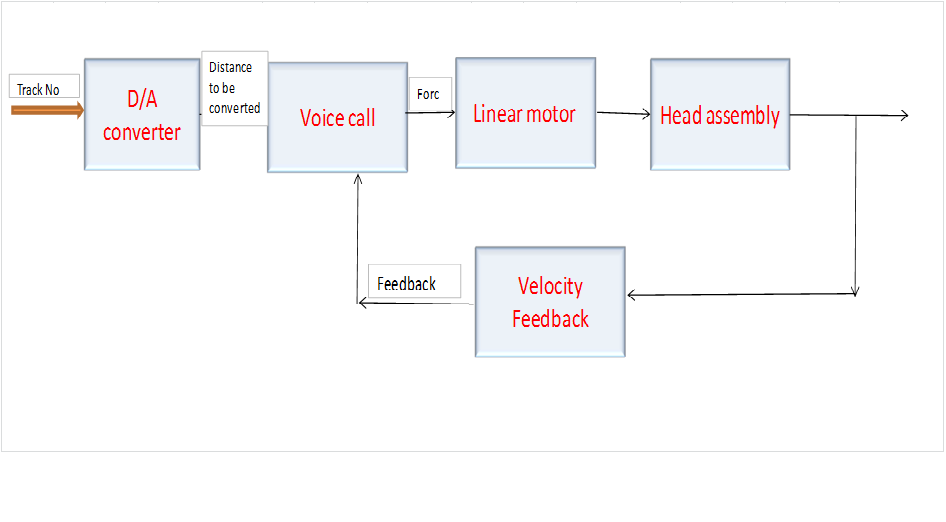

Closed loop disk drive

- Hard disk info – reference info positioning

Ways for storing head positioning information

- Servo tracks

- Servo surface

- Linear voice coil mechanism – control linear motor position using feedback control – moves head at different velocities

- Head acceleration based on distance

- Automatic reposition

Closed loop positioning system

Advantage

- Accurate head positioning on desired track

- Less access time

- Cost twice or thrice of open loop system

- Suitable for high performance system

Size & capacity

- Inches – platters diameter

- Sizes – 20, 14, 101/2, 8, 51/4, 31/2, 21/2 inches

- Capacity – size & technology

- 14 inch HDD – 20MB & 21/2 inch HDD – 40GB

To have more data capacity,

- Higher track density

- Higher recording density

- Better Packaging methods

Hard disk drive organization

- Both electronic & electromechanical subsystems, viz.,

- R/W Head

- Disks

- Spindle motor

- Positioning mechanism

- Air Circulation System

- Air Filters

- In Winchester HD – sealed head disk assembly (HAD) with R/W head, disks, band actuator assembly & air circulation system

Head Types

- Manganese/Zinc ferrite head

- Thin film head

Standard interface for hard disk connection

- SMD, IDE, EIDE, SCSI, IPI, ESDI, ST506/412

- In ST506/412 interface,

- Radial/Data Cable - Data Sent/received on separate cable

Daisy Chain Cable

- Control sgls sent through to 1st HDD

- Same sgls extended to 2nd HDD by another cable

Data organization on hard disk

- Magnetic tracks – into sectors

- Currently, Soft sector format

- In ID Field,

- Track Number

- Head Number

- Sector Number